4.1 The morphology of microscopic surface cross-section of the coating

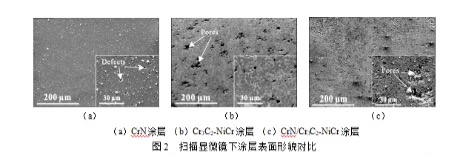

The surface cross-sectional morphology is closely related to the matching properties, wear resistance, fatigue strength, contact stiffness, vibration and noise of mechanical parts, and has an important impact on the service life and reliability of the valve. Therefore, the three coatings were observed with a scanning electron microscope, and the comparison results are shown in Figure 2 and Figure 3. Figure 2 shows the surface morphology of the coating, in which the surface of the CrN coating is the densest; the forming quality is good, and there are small holes on the surface; there are a large number of holes on the surface of the Cr3C2-NiCr coating; the surface of the NiCr coating is relatively rough with a small number of holes, and the CrN coating film cannot completely cover the pores of Cr3C2-NiCr coating.

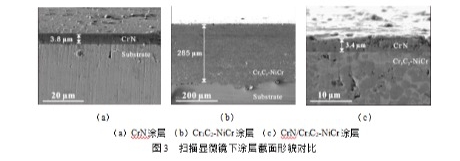

Figure 3 shows the cross-sectional morphology of the coating, in which the CrN coating is well bonded to the substrate without defects. The average thickness of the coating is about 3.8µm; the Cr3C2-NiCr coating is well bonded to the substrate, and the average thickness of the coating is 285µm; the CrN layer in the CrN/Cr3C2-NiCr coating is well combined with the Cr3C2-NiCr intermediate layer, and there are small holes in the coating; the coating density is reduced, and the average thickness of the coating is about 3.4μm.

Figure 2 A comparison of morphology of the coating surface by microscopes

Figure 3 A comparison of cross-section of the coating surface by microscopes

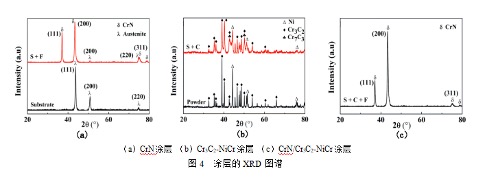

Figure 4 The coating

4.2 The analysis of the phase of the coating

The CrN coating, Cr3C2-NiCr coating, and CrN/Cr3C2-NiCrCrN coating were analyzed for phase, and the XRD patterns are shown in Figure 4. The results show that the CrN coating is mainly composed of fcc-CrN. The Cr3C2-CrNi coating is mainly composed of Ni, Cr3C2 and Cr7C3, and the surface of CrN/Cr3C2-CrNi composite coating is also composed of fcc-CrN; no other constituent phases were found.

4.3 A comparison of parameters of coatings

The hardness, elastic modulus and elastoplastic factor of CrN, CrN/Cr3C2-NiCr coatings are shown in Table 1. The ratio H/E of hardness and elastic modulus is the elastic factor. The higher the ratio is, the better the wear and impact resistance becomes. H3/E2 is the plastic factor. The higher the ratio is, the better the ability to resist plastic deformation become. By comparison, the elastoplastic factor of the CrN/Cr3C2-NiCr coating is relatively high, indicating that the coating has better wear resistance and fracture toughness.

Table 1 A comparison of CrN, CrN/Cr3C2-NiCr coatings

| Coatings | Hardness/GPa | Elastic modulus/GPa | Elastic factors (H/E) | Elastoplastic factor (H/E) |

| CrN | 24.5 ± 3.8 (2272 HV) | 287.4 ± 23.1 | 0.085 ± 0.011 | 0.179 ± 0.064 |

| CrN/Cr3C2-NiCr | 33.3 ± 6.4 (3081 HV) | 365.3 ± 47.1 | 0.091 ± 0.009 | 0.277 ± 0.101 |

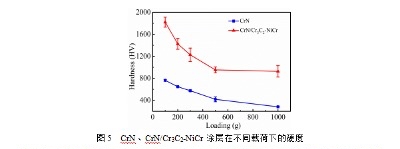

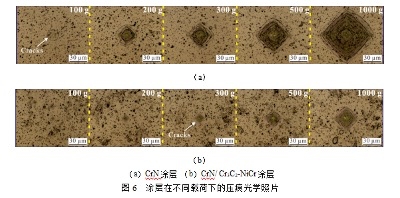

4.4 Bearing capacity and fracture toughness

The hardness of CrN and CrN/Cr3C2-NiCr coatings under different loads was analyzed, as shown in Figure 5. As the indentation load increased, the surface hardness decreased. It can be seen from Figure 5 that the surface hardness of CrN/Cr3C2-NiCr coatings is much higher than that of CrN coatings. Figure 6 shows the OM images of surface indentations under different loads. It can be seen that cracks appear in the CrN coating under all loads. Cracks appeared in CrN/Cr3C2-NiCr coatings under loads of 300g, 500g and 1000g, but no cracks appeared under 100g and 200g of indentation loads. Therefore, the bearing capacity and toughness of CrN/Cr3C2-NiCr are superior to CrN.

Figure 5 Hardness of CrN, CrN Cr3C2-NiCr coatings under different loads

Figure 6 Optical photographs of indentation of coatings under different loads

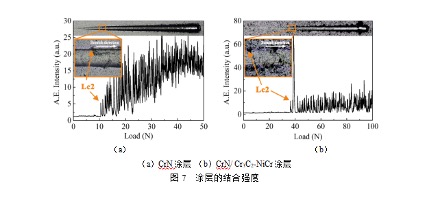

4.5 Bonding strength

Bond strength refers to the force required to peel the metal coating from the base metal or intermediate coating. The bonding strength of the two films was tested by scratch, and the acoustic signal was recorded synchronously in the detection process. The results are shown in Figure 7. The bonding strength of a single CrN coating is 10.0N, and that of CrN/Cr3C2-NiCr coatings is 37.0N. The introduction of the Cr3C2-NiCr intermediate layer improves the ability of the substrate to resist plastic deformation, thereby improving the adhesion of the CrN coating.

Figure 7 Bonding strength of coatings

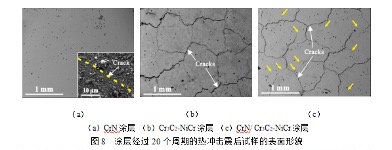

Figure 8 Surface morphology of coatings after 20 cycles of thermal shock

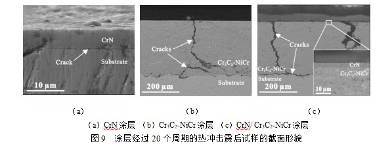

Figure 9 Cross-section morphologies of coatings after 20 cycles of thermal shock

4.6 Thermal shock performance of coatings

The surface and cross-sectional morphology of the coating after 20 cycles of thermal shock are shown in Figure 8 and Figure 9. It can be seen from Figure 8 that large reticular cracks appear on the surface of Cr3C2-NiCr coatings, and reticular cracks also appear on the surface of CrN/Cr3C2-NiCr coatings. There is no obvious crack on the surface of CrN coatings. Cracks are only visible under high magnification. From the cross-sectional morphology of Cr3C2-NiCr and CrN/Cr3C2-NiCr in Figure 9, long vertical cracks are penetrating the coating in the Cr3C2-NiCr intermediate layer, and typical cracks appear at the interface with the substrate. The intermediate layer has a great influence on the thermal shock resistance of the composite coating.

4.7 Friction and wear

The UMT reciprocating high-temperature friction testing machine was used to test the tribological properties of the coating at gradient temperatures such as 25ºC, 150ºC, 250ºC, 350ºC, 450ºC, and 550ºC. The single sliding stroke is 5 mm; the normal load is 3N, and the frequency is 2Hz. The test time is 15 minutes. The frictional pair is a small WC ball with 6 mm. The Micro MAXTM three-dimensional surface profiler was used to characterize the profile of the worn surface of the sample. For better comparative analysis, friction tests were carried out on all three coatings.

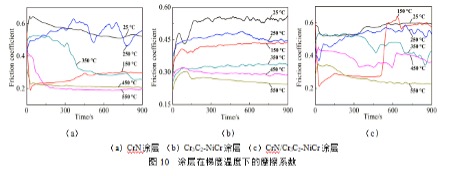

Figure 10 Friction coefficient of coatings at gradient temperatures

Figure 10 shows the friction coefficient of the coating at gradient temperature. As the temperature increases, the friction coefficient generally decreases. At the temperature of 25ºC, the friction coefficients of the three coatings are relatively close, and the CrN/Cr3C2-NiCr coating is slightly higher; at the temperature of 150ºC, the friction coefficients of the coatings are significantly reduced, and the CrN coating decreases to an average of about 0.2, with the greatest drop. The Cr3C2-NiCr coating decreased the least. The average friction coefficient reached 0.42. The friction coefficient of the CrN/Cr3C2-NiCr coating was small in the early stage, and it suddenly rose sharply at about 500s, indicating that the coating had been pierced; the friction coefficients of the three coatings increased in different degrees at the temperature of 250ºC compared with the temperature of 150ºC.

In the friction process, the friction coefficient of the CrN coating fluctuated greatly. The average friction coefficient was 0.57. The average friction coefficient of Cr3C2-NiCr coatings was 0.45, and that of CrN/Cr3C2-NiCr coatings reached 0.55. When the temperature rises to 350ºC, 450ºC, and 550ºC, the friction coefficient of CrN coatings decreases, reaching the lowest at 0.19 at 550ºC; the average friction coefficient of Cr3C2-NiCr coatings reaches the lowest at 0.25 at 550ºC; the average friction coefficient of the CrN/Cr3C2-NiCr coating fluctuates greatly, and the coating may be pierced in the friction process. The average friction coefficient reaches 0.25 at 550ºC, which is the same as the average friction coefficient of the Cr3C2-NiCr coating.

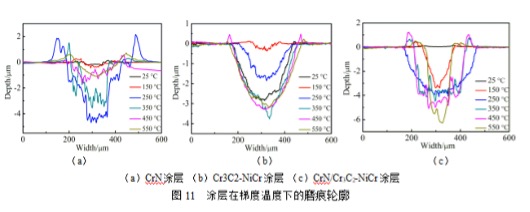

Figure 11 Abrasive contour of the coating at gradient temperature

Figure 11 shows the wear profile of the coating at gradient temperatures. The wear profile of the CrN coating is deeper at 250ºC and 350ºC, indicating that the coating wears more seriously; the wear depth of Cr3C2-NiCr coatings is the shallowest at 150ºC and deepens at 250ºC. The wear depths are closed at temperatures of 350ºC, 450ºC, and 550ºC, about 3.3µm. The wear depth of CrN/Cr3C2-NiCr coatings gradually deepened with an increase in temperatures, reaching a maximum of 6.2µm at 550ºC. The coating has poor wear resistance. However, the wear width of the CrN/Cr3C2-NiCr coating at each temperature is narrower than that of the CrN and Cr3C2-NiCr coatings. The composite coating can still provide good support at high temperatures.

5. Conclusion

Through the design of CrN/Cr3C2-NiCr composite coatings for the sealing surface of high-temperature wear-resistant ball valves and the study of its mechanical and tribological properties under high temperatures, the following conclusions are came:

(1) The CrN/Cr3C2-NiCr composite coating has better hardness, and the introduction of the middle layer provides good support for the top film and improves the fracture toughness of the coating.

(2) As the temperature increases, the hardness of the composite coating decreases gradually, but it still has a high hardness at 550°C.

(3) The bonding strength of the composite coating is high, and the introduction of the Cr3C2-NiCr intermediate layer improves the ability of the substrate to resist plastic deformation, thereby improving the adhesion of CrN. The hardness, modulus and thermal expansion coefficient of the coating are less different; the interface matching is better, and the composite coating shows excellent thermal stability.

(4) The friction coefficient of the composite coating is low, and the coating has almost no wear. The composite coating still maintains a high hardness at high temperatures, and its wear forms are mainly adhesive wear, oxidative wear and slight abrasive wear.