1.

Válvula de

2.

Projeto

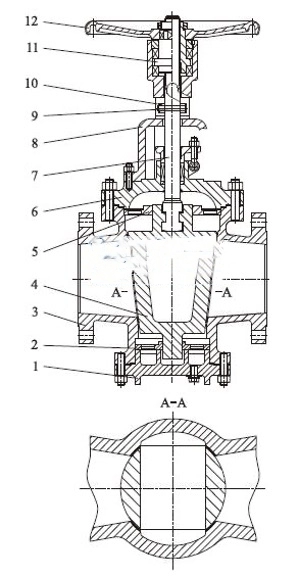

The end of the valve body is flanged, and the flow channel is Venturi ruled, that is, the cross-sectional area of

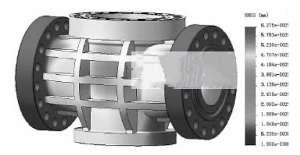

According to actual inspections and tests, the parts where stress concentration has the greatest impact on the deformation of the valve body are in the cavity and sealing surface of the valve body, thus affecting the sealing of the valve. For the high-pressure valve body, integral casting ribs are provided on the outside (Figure 2 and Figure 3) or the wall thickness of the valve body is increased to ensure that the valve body has sufficient rigidity at high pressure. The sealing surface of the valve body is designed as an internal convex structure, which makes it more manufacturable and convenient for machining and grinding. When the valve is fully closed, the middle cavity is suitable for purging.

4.2.

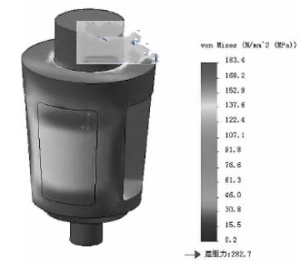

Figura 4 Distribuição da carga de tensão estática do plugue

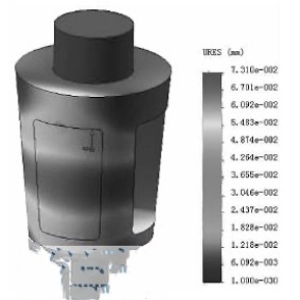

Figura 5 Distribuição do deslocamento estático de carga do plugue

O plugue geralmente é feito de carboneto de aço carbono fundido. Para classe de pressão acima de 600, é aconselhável usar carboneto de superfície de aço carbono forjado ou usar o processo de endurecimento da superfície de aquecimento de aço inoxidável martensítico fundido; A dureza após o tratamento térmico é controlada entre 35 a 40 hrc e a corrosão e a ligação são impedidas após a moagem. A superfície de vedação do corpo da válvula e do plugue é revestida com liga dura, o que não apenas evita a confissão, mas também prolona a vida útil da válvula.

4.3.Haste da

The sealing structure of the bonnet is designed as a concave-convex surface or a ring connection to meet the requirements of different pressure levels. For large-diameter valves, the split design of the bracket and bonnet is adopted. In addition, the valve stem hole of the metal seated plug valve bonnet is provided with an upper sealing seat, which cooperates with the 90° cone surface at the end of the valve stem to form the upper sealing pair of the valve, meets the requirements of online replacement of packing and is easy to maintain. There is a guide groove on the upper part of the valve bracket, and the guide groove cooperates with the roller to complete the two actions of lifting and rotating the plug. The flange at the upper end of the bracket is designed to install various actuators. The bottom cover is provided with discharge holes, which can be used to remove and purge the dirt in the body cavity.

Fabricação e inspeção

English

English