1.Princípios

1.1Análise das condições operacionais da válvula

Hydraulically controlled slow-closing butterfly valves are divided into two types, that is, heavy hammer types and energy storage types. There are two main operating conditions, including centrifugal pump conditions and hydraulic turbine conditions. Valve-opening centrifugal pump conditions including centrifugal mixed-flow pumps. Start the pump first, and then open the valve after a predetermined time. Open-valve turbine conditions: first, open the bypass valve to balance the pressure, and then open the valve; open the turbine at last. Various operating conditions require the valve to be closed when a shutdown or power failure occurs.

Quando a válvula é aberta, a válvula solenóide muda de direção e o acumulador libera energia; O óleo hidráulico entra no cilindro através da válvula de velocidade, da válvula de mão única e da mangueira de alta pressão e empurra o pistão para se mover; A válvula se abre de acordo com o procedimento definido e a placa borboleta se abre até o limite mecânico. Defina uma posição totalmente aberta.

2.Parâmetros

| Projects Nominal pressure/MPa |

Parameters 0.6 to 4.0 |

| Nominal diameter/mm | DN300 to 2000 |

| Eliminating water hammer caused by a stopped pump/% Leakages at a fully closed state |

Greater than and equal to 80 Zero leakage |

| Noise/db Computer control |

Less than 80 (1 meter away) DCS passive contact line joint control interface |

3. Structural Design

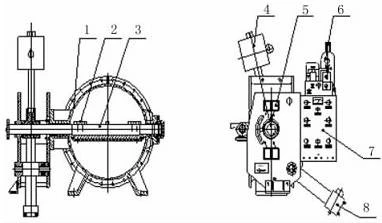

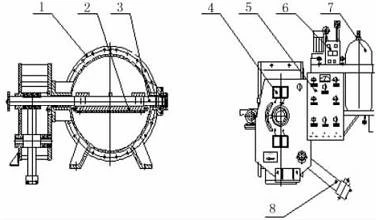

The hydraulically controlled slow-closing butterfly valve is composed of three major parts, that is, the valve body, the hydraulic drive device and the electrical control system; according to the closing power, it is divided into two types, that is, the heavy hammer type and accumulator type. Figure 1 shows the structure of the hammer type hydraulically controlled slow closing butterfly valve, and Figure 2 shows the structure of the accumulator type hydraulically controlled slow closing butterfly valve.

1. Valve bodies 2 Butterfly plates 3. Valve stems 4. Heavy hammers 5. Travel switches

6. Hydraulic stations 7. Electric control cabinets 8. Hydraulic cylinders

Figure 1 Heavy hammer hydraulic control slow closing butterfly valves

1. Valve bodies 2 Butterfly plates 3. Valve stems 4. Travel switches 5. Electric control cabinets

6. Hydraulic stations 7. Accumulators 8. Hydraulic cylinders

Figure 2 Accumulation type hydraulic control slow closing butterfly valves

The heavy hammer type is an early transmission structure, which is characterized by the accumulation of potential energy by the lifted heavy hammer. In the case of an emergency shutdown, the heavy hammer falls rapidly; the potential energy is released; the kinetic energy is increased, and the butterfly plate is quickly closed. The advantage is that the energy accumulation is reliable, and the closing speed is reliable and stable. However, the disadvantage of the heavy hammer type is that it occupies a large space (the radius of rotation of the weight), and the weight of the heavy hammer is heavy. During operation, if the transmission chain is loose, it will cause much vibration.

The accumulator type is a new type of drive mechanism, and its opening and closing are all released by the energy stored in the energy storage tank. It has advantages of small sizes and light weights, and the hydraulic system being very reliable to maintain pressure. It has disadvantages of high costs, higher requirements for the hydraulic system. The valve body and the hydraulic drive device are tightly installed as a whole, which is called a conjoined type, and when they are installed separately, it is called a split type. The integral type has a compact structural structure. The distance between the output oil pipes is short; the flow resistance is small, and the emergency shutdown time is short. The hydraulic station is subjected to much vibration, and it is inconvenient for maintenance and disassembly. The split type places the hydraulic station outside the valve body to avoid the hydraulic station parts from working in continuous vibration. At the same time, it is not necessary to disassemble and assemble the huge hydraulic station to maintain the main body of the valve, but its disadvantage is that it occupies large space, the conveying pipeline is long, and the flow resistance is great, which easily affects the opening and closing speed.

English

English